The shape of disc springs is conical. The manufacture of disc springs has a long history in Europe. But in North America, the manufacturing industry of disc springs is booming and gradually accepted. Disc spring was first invented by J. Belleville of France more than 100 years ago. In the early 1930s, engineers (G.M.) Almen and laszio developed theory, formulated production and quality standards DIN 2092 and din 2093. As the first industrial standard of Belleville spring, these standards have been accepted all over the world and spread all over Europe. At present, they have been widely used by many multinational companies. Japan has set its own standards, but the United States has not yet set its own industrial standards for Belleville springs. Many American manufacturers use DIN standard as the quality standard of Belleville spring. In 1980, China also formulated corresponding standards according to DIN regulations, and revised them in 1992. The standard number is GB / t1972-2005, which specifies the size series, technical requirements, test methods, inspection rules and design calculation of Belleville spring.

Disc spring characteristics:

● short travel and heavy load. ● small space required. ● easy to use in combination.

● easy to repair and replace. ● high economy and safety. ● long service life.

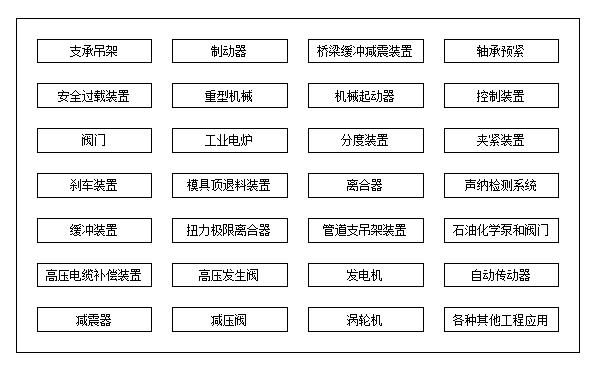

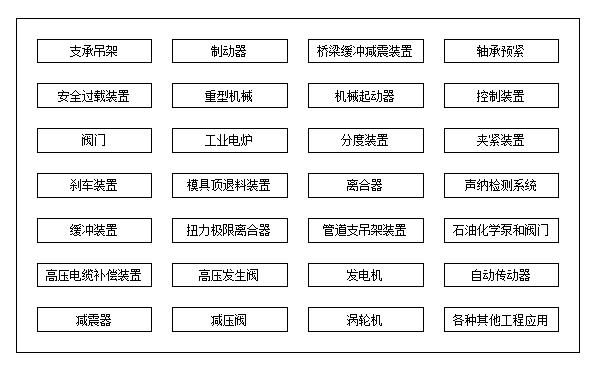

Application of Belleville spring:

1. Temperature resistance range: - 180 ~ 600 ℃ mubea disc spring

2. Features

◇ relaxation of pretension caused by thermal expansion and cold contraction

Due to the different speed of hot expansion and cold contraction of bolts, flanges and other connecting parts, the preload is changed repeatedly. The high-temperature disc spring keeps the preload stable to prevent bolt fatigue and gasket failure.

◇ relaxation of preload caused by change of medium pressure

The disc spring can compensate for the change of preload caused by the change of medium pressure and prevent the bolt and gasket from failure.

◇ mechanical vibration causes relaxation of preload

The restoring force of disc spring can effectively balance the bolt looseness caused by mechanical vibration, and ensure the long-term reliability of the equipment.

3. Material: alloy steel imported from Germany

Standard: the disc spring shall comply with din2092 design standard and din2093 manufacturing standard.

Material: Inconel718 51CrV4 x22crmov121 17-7ph

Surface treatment of Belleville spring:

● general surface treatment: add lubricating oil after phosphating treatment.

● special surface treatment: electroplating, galvanizing, Dacromet, plastic spraying, electroless nickel plating, geomet, baking paint, etc. If special surface treatment is required, please discuss with our company.